Olive Oil Webinar

In Brief…

Cycle A’ consists of three topics: Olive Grove, Olive Oil and Olive Mill.

Olive Grove: All the necessary information for the care of the olive grove, cultivation of the soil, pruning, irrigation and fertilization based on modern practices.

Olive Oil: All the key points and details to be followed, from harvest to filtering and storage according to the latest methods and practices. Detailed discussion of the new types of crushers and malaxers. The new equipment of the small and medium sized oil mills of Italy and Spain are also discussed. Many pictures and videos of exemplary processing in foreign olive mills are presented.

Olive grove, olive oil and cultivation practices (4 hours)

Chemical parameters of olive oil: Acidity, K indexes, Peroxides and their practical meaning.

Sensory criteria of quality and their importance

What phenolics are and how they affect olive oil

Cultivation practices. To till, or not to till?

Pruning: Basic principles, how much? How often? Consequences

Irrigation: Why irrigate? How useful is it?

Fertilization: All the basic principles for correct fertilization

Super High Density planting: How efficient is it?

How and when to harvest?

Calculation of the most appropriate harvest time

Modern harvesting methods – Mechanized harvesting

Importance of immediate transport and milling of olive fruit

All the factors in harvesting and processing, leading to the production of quality olive oil (5hours)

Ideal harvest time – Maturity index

The many implications of late harvest

Explanation of the processing stages in the Mill

The great importance of clean washing water and clean equipment

The three types of crushers: Pictures and explanations

Malaxation times and temperatures: Their effects

Abolition of malaxers? The quick heating of olive paste

Decanters: 2 or 3 phase? Advantages and differences

Filtering: When? Why? Methods

Olive oil storage: Nitrogen or Argon?

Small professional milling equipment: Pluses and minuses

Vasilis Frantzolas Vasilis Frantzolas, born in Athens, has a long family tradition in the wholesaling and retailing of olive oil. He studied as agronomist engineer and then completed his studies on civil engineering, M.Sc. (Athens) and construction management, M.Sc (USA). In 2009 he received a Master’s degree in Food Policy at City University London. His education and training in the sensory evaluation of olive oils began in 2003 and he has then attended various seminars in Greece and Italy concerning the sensory evaluation of olive oil.

Read more

Location

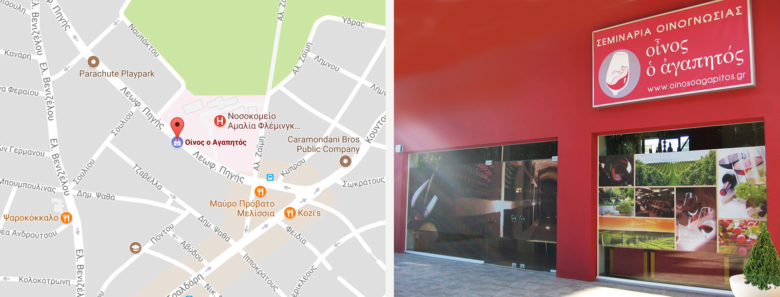

Seminars take place in the “Οινος ο Αγαπητός» Hall in Melissia. Address : Pigis Av. 15, 15127. The Hall is across the” Bobola” section of “Amalia Fleming” Hospital.

The hall is equipped with modern audiovisual equipment, the location is accessible by bus and allows easy car parking.

Participation Cost

A’ Cycle Seminar €170

Participants of both cycles – A ’and B’-will have a 10% discount from the total cost.

Ways of Payment

An advance payment is not required, to subscribe for the seminar. In case of cancellation a notice must be sent at least three days before the seminar takes place, by mail or phone. Otherwise 50% of the cost is due, which however can redeemed by participating in the next available seminar.

Payment is made on the spot, on the day of the seminar, either in cash or with a credit/debit card (except Diners and American Express) in POS machine.

Proof of Participation

Participants that complete both cycles A’ and B’ of training obtain a Proof of Participation certified by Swiss Approval Technische Bewertung.

Extra Benefits

Participants that complete both cycles A’ and B’ of training will receive:

A special, IOC specification, blue olive oil tasting glass

Free submission of olive oil samples for sensory evaluation

All participants in either of the cycles A’ or B’ can bring two samples of their own production olive oil for sensory evaluation (not chemical analysis) without cost.

The samples should be in well-sealed, 250-500ml, labeled bottles. The label should include: A: The name of the producer. B: The area. C:.The variety. D: The date of milling E: The name of the milling factory, if available.

The evaluation results will be sent by e-mail, within 2-3weeks.